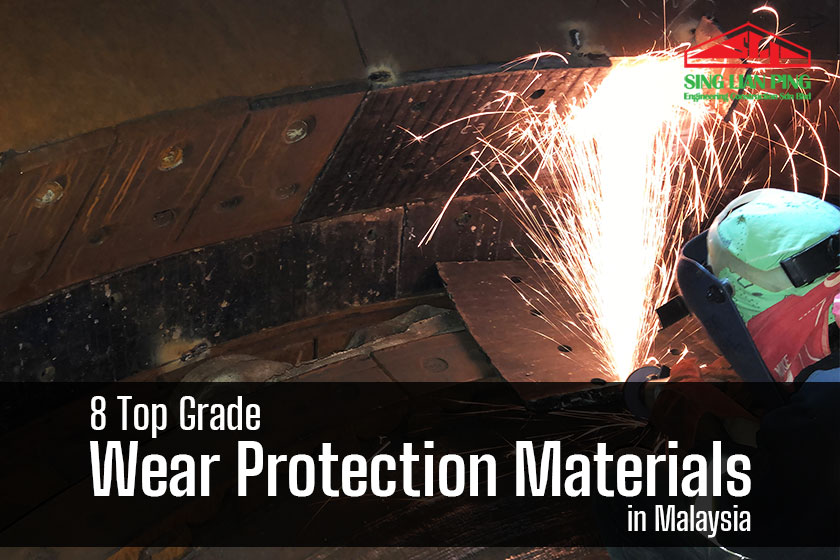

List of Abrasion Resistant Materials in Malaysia

Protect your project with abrasive wear resistance.

Generally, industries dealing with abrasion use high wear resistant material. Also known as abrasion-resistant materials.

Hence, with 40 years of engineering, SLP gained knowledge of several abrasion resistant coatings.

So here are the latest abrasion resistant materials in Malaysia based on the installation methods.

Top Grade Abrasion Resistant Materials in Malaysia

1. ABRESIST Abrasion Resistant Materials

Properties

-

- Hard and smooth for good flow

- For locations with chemical stress

- US FDA approved

- Max operational temperature of 350°C

Basically, a high-density mineral structure called basalt forms ABRESIST. Consequently, this makes it ideal to coat linings with low wear resistance.

Moreover, its magnesium and iron-rich rock properties can effectively protect against abrasion. Thus, it is a reliable mineral-based choice for abrasive wear resistant materials.

Accordingly, its applications include linings for boiler refractory installation or abrasion resistant plates.

2. KALCRET Hard Compound

Properties

-

- Applied by troweling, pouring or spraying

- Jointless lining

- Ideal for geometric surfaces

- Diverse thickness

- Max operational temperature of 1200°C

- Easily combined with other materials

- Easy repairs

KALCRET has hard mineral elements for high-performance wear resistance made by Kalenborn.

Thus, the wear resistant ceramics can coat large surfaces in a short time. This will certainly quicken plant restoration for burning facilities.

To conclude, this wear resistance coating is ideal for many applications such as abrasion resistant coatings for steel.

So, if you’re in the power, steel, or cement industry, these Kalenborn wear protection solutions can help you.

3. KALOCER Wear Resistant Ceramics

Properties

-

- For locations with chemical stress

- US FDA approved

- Ideal for geometric surfaces

- Max operational temperature of 1200°C

- From 1.5 mm thickness

- Light-weight

The main component of this oxide ceramic material is aluminum oxide. As a result, KALOCER is very protective against abrasion.

Even so, engineers must carefully pick the right size and distribution. Correspondingly, only then will you reach its full abrasive wear resistance.

Not to mention, you can produce KALOCER into very smooth and thin tiles. Thus, wear resistant linings can easily line bunkers, chutes, concrete mixers, or cyclones.

Suggested read: 6 Tips to Choose the Best Refractory Contractor in Malaysia

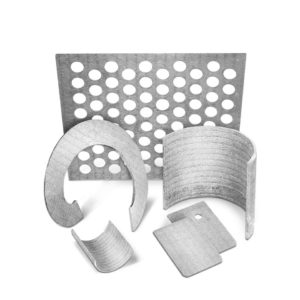

4. KALCOR Wear Resistant Ceramics

Properties

-

- For locations with chemical stress

- Max operational temperature of 1200°C

- For cylinders from 12 mm thickness

- Withstands temperature changes and thermal shock

- Custom-made sizes

Tiles, pre-cut shapes, and cylinders form the Zirconium corundum. Therefore, this abrasion resistant ceramic can be custom-made. For example, to line hot sinter chutes, hot gas pipelines or extraction separators.

5. KALCAST Hard Cast Iron

Properties

-

- Paired with specific needs

- Smooth

- Max operational temperature of 350°C

- 15-70 mm thickness

- Pipe’s inner diameter of 40-800 mm

Basically, alloy components with added Manganese are the main elements of KALCAST. So, these abrasion resistant products ensure the highest wear protection and impact resistance.

Moreover, applications include coating concrete mixers, grinding rollers, and plates in a vertical mill as well as coal dust piping in power stations.

Equally important, this high wear-resistant material can be custom-made ready for installation.

6. KALMETALL Hard Facing

Properties

-

- Standard thickness from 5 mm

- Welded overlay of 3-18 mm thickness

- Max operational temperature of 750°C

- Self-supporting structures

- Ready-to-install custom components

In general, KALMETALL is made of hard overlay welded steel. Thus it is one of the abrasive wear-resistant materials. Moreover, its base can be a standard or special plate depending on the application.

Furthermore, the hard overlay welding consists of a C-Cr-Fe system. Also, it contains chromium carbides which provide impact resistance of up to 820 HV.

Likewise, you can also adjust the alloy mix. This can be based on wear resistance, impact resistance, and temperature. Hence, KALMETALL is a suitable abrasion resistant coating. Especially for wear resistant cyclone linings.

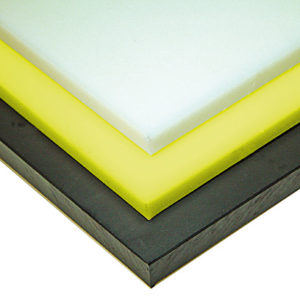

7. KALEN 1006 Thermoplastic

Properties

-

- Slide-promoting wear protection

- Smooth flow of materials

- Custom lining

- Jointless welding of plates

- Special edging system

- Stainless steel fastening element

Basically, KALEN is made out of thermoplastic plates. Which makes it an anti-friction and corrosive protective material. They effectively help prevent goods from sticking during transport.

Not only that, but this abrasion-resistant material also matches perfectly to the lining shape based on the thickness and size.

Thus, it is ideal as wear resistant coatings and linings for silos, loading buckets, and dumpers. As well as vibrators or air shock blowers are no longer needed for fine-grained bulk goods.

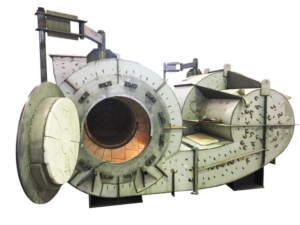

8. Combined Lining Abrasion Resistant Linings

Generally, SLP ensures maximum abrasive wear resistance in each combined lining.

For example, a stacker reclaims the coal in a coal transportation process in a power station. Then, multiple transfer chutes transport the coal to storage.

Accordingly, SLP installed KALOCER wear-resistant ceramic on the sliding area. Also, KALMETALL on the impact area for optimum wear resistance.

Therefore, compound lining depends on many factors. Such as the mechanical stresses, temperatures, abrasion levels, or expenses of the application.

Protect your Plant with the Best Abrasion Resistant Materials

There are many things to consider before making the decision, but it shouldn’t be that difficult.

All in all, wear resistant materials entirely depend on your application needs and plant conditions.

However, if you need more detailed or customized advice, we can provide a list of wear resistant materials for your job. Regardless of any of your needs for low wear resistance project conditions.

Suggested read: How to Choose the Right Refractory Material in Malaysia