Corrosion is never welcome so prevent it with corrosion resistant materials today.

Chemical plants and petrochemical plants need top-grade corrosion-resistant materials.

This is due to exposure to corrosive materials that can cause corrosion.

Moreover, corrosive acid resistant materials prevent further damage from corrosive chemicals while reducing downtime.

SLP not only provides refractory materials but also has a line of anti rust materials resistant to acid to protect your plant.

What materials can be used to stop corrosion?

If you are asking what material is acid proof and corrosion resistant, here is a list for you:

More about corrosion resistance from the metal experts.

What is the most corrosion-resistant material?

1. PENNGUARD® Corrosion Resistant System

Properties

-

- Chemical resistant

- Heat resistant up to 200°C

- Resistant to thermal shock

- Lightweight

- Long life-span

Brick chimneys and steel chimneys are heavily exposed to corrosives. So, one solution is to use acid-resistant lining.

The PENNGUARD® System is suitable for a wide range of operations such as wet flue gas and untreated flue gas with high SO3 content.

Also, it can resist high temperatures of up to 200°C and even higher temperatures under a short period of time.

Moreover, at just about 1.2kg per square foot, the acid-resistant PENNGUARD® lining is very resilient in seismic conditions.

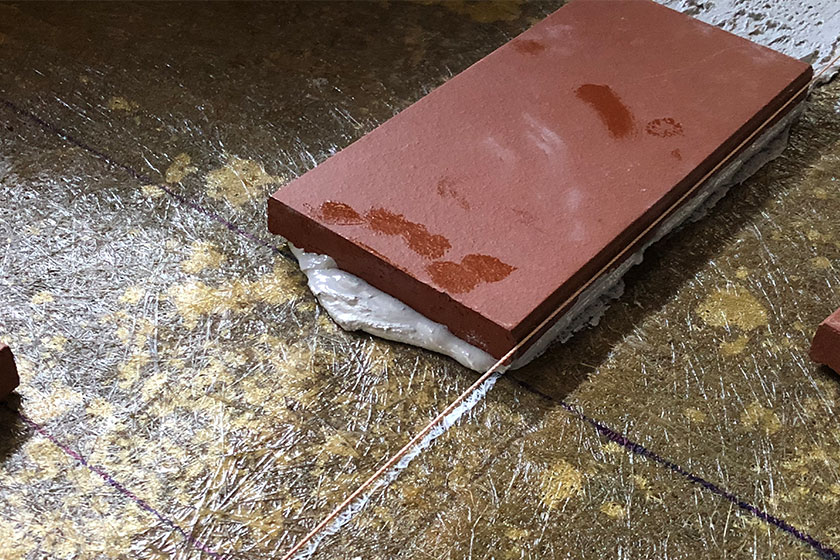

2. Acid Resistant Tiles

Properties

-

- Heavy duty

- Acid-resistant

- Impact-resistant

- Thermal shock resistant

Acid-proof tiles have a lot of defining qualities. Such as its various sizes and thickness to suit the application. Accordingly, this quality is based on the levels of thermal shocks, impact forces, and load.

Not to mention, these non-corrosive tiles are also considered low maintenance with a long life span. So, you don’t have to worry about constant care for corrosion protection.

3. Acid Proof Bricks

Properties

-

- Custom sizes available

- Long life span

- Heat resistant

- Fits easily

Sometimes, acid-resistant industrial tiles are not suitable for an application. Hence, they are the ideal option as one of the acid proof materials.

Basically, industrial acid-proof bricks are well known for their resistance against corrosive materials and heat.

Hence, it is very suitable to line large tanks that need physical stability. Such as cement plants, power plants, steel plants, and chemical plants.

Suggested read: 8 Top Grade Wear Protection Materials in Malaysia

4. Monolithic Lining Systems

Incorporate this strengthened fabric. So these corrosion-resistant materials can provide seamless flooring solutions.

PENNTROWEL®

Used as a concrete or concrete bonding agent, this liquid epoxy resinous primer can adhere to both concrete and steel substrates. Also, one of its efficient properties is its ability to be applied to damp or dry concrete or steel substrates.

FURALAC®

This chemical-resistant furan resin-based brick mortar is primarily used for bonding brick or tiles. Furthermore, it has a high bond strength, chemical resistance, and effective curing and handling features.

Thus, it is a reliable system for corrosion-resistant coatings. Such as brick and tile floors, tanks, chimney linings, and equipment linings.

5. Corrosion Resistant Brick Mortar / Tile Grouts / Joint Fillers

Mortar, grouts, and fillers are acid-resistant resin-based compounds. Generally, they are even better than conventional epoxy-based grouting compounds.

Additionally, PENNCHEM is a grouting system that can resist impact, vibration, load, and chemicals. Thus, it is ideal for low shrinkage applications.

6. Polymer Concrete

The heavy-duty castable, polymer concrete is one of the high corrosion resistance materials. Similarly, this silica-filled concrete performs well under high chemical concentrations and raised temperatures.

Another benefit is it is cheaper than bricks. However, it has remarkable physical strength, low permeability, and abrasion resistance.

Also, these anti-corrosive materials are easily installed and last long. Thus resulting in a better project outcome.

Corrosion Resistant Materials Protect Your Project

Review your project requirements properly, then make the decision

Corrosion-resistant materials have no one-fits-all solution. This is because it depends on various factors. For example, the chemicals, their concentration, parameters, temperatures, impact, and load.

Hence, the decision should not be taken lightly. So consult an acid-proof materials specialist. Then they can help you meet your application needs and plant requirements effectively.

Need more detailed or customized advice? That’s why we are here to help with all your project conditions.

Suggested read: 6 Tips to Choose the Best Refractory Contractor